Best Warehouse Audit Tool to Improve Performance

How can you determine whether your warehouse is operating at a satisfactory level? This warehouse audit tool, or Warehouse Audit Checklist, empowers you to pinpoint areas that require enhancement and gauge the performance of your warehouse. What is a Warehouse Self-Assessment Audit? A Warehouse Self-Assessment Audit is a systematic evaluation of your warehouse’s operations

1 Files

31 Purchases

Unlimited access, anywhere, anytime

Upgrade to Student or Pro plan to avail more discounts and perks

Files

- WAREHOUSE SELF-ASSESMENT TOOL628.1 KB

What is a Warehouse Self-Assessment Audit?

A Warehouse Self-Assessment Audit is a systematic evaluation of your warehouse's operations to identify strengths, weaknesses, and areas for improvement. It's a crucial tool for ensuring optimal efficiency, safety, and productivity within your warehouse. By conducting regular self-assessments, you can proactively address potential issues, enhance operational processes, and maintain high standards of performance.

This Self-Assessment Warehouse Audit Tool also:

- Encourages employee involvement and responsibility in enhancing warehouse operations.

- Promotes staff reflection on their roles and contributions to essential warehouse processes.

- Provides an avenue for staff to view and reflect on their peers' contributions assessment.

- Centers around cultivating employees' judgment skills.

"Inbound flow handling, product-to-location assignment, product storage, order-to-stock location-allocation, order batching and release, order picking, packing, value-added logistics activities, and shipment (Ackerman, 1980)."

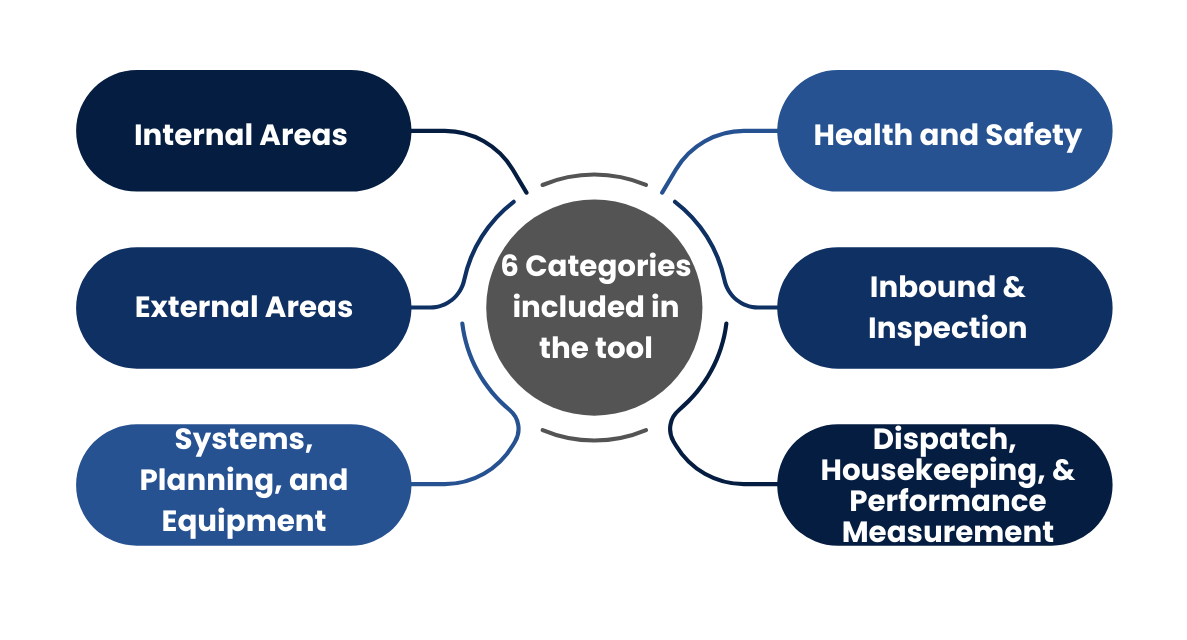

6 Categories Included in Tool

This warehouse audit tool comprehensively examines the characteristics (indicators) and dimensions of warehouse management across six key areas:- Internal Areas – Encompassing security checks, safety briefings, floor plans, ventilation, and more.

- External Areas – Covering aspects such as signboards, routes, lighting, parking, and more.

- Systems, Planning, and Equipment – Encompassing IT systems, mechanical handling equipment, key warehouse processes, goods movement, vehicle booking systems, and vehicle scheduling.

- Health and Safety – Addressing internal and external health and safety measures, staff awareness, and more.

- Inbound & Inspection – Focusing on non-conformance in product and packaging, as well as the scheduling of vehicle arrivals.

- Dispatch, Housekeeping, and Performance Measurement – Encompassing picking, warehouse performance management, training, shift allocation, employee utilization, and more.

For each category, select one of the five choices on the Likert scale. If "N/A" is selected, it will not be factored into the total score. Upon completing the Warehouse Audit Checklist, you will receive three graphs, as depicted below.

For each category, select one of the five choices on the Likert scale. If "N/A" is selected, it will not be factored into the total score. Upon completing the Warehouse Audit Checklist, you will receive three graphs, as depicted below.

Over the past decade, warehouse operations have become more complex. This complexity is evident in the adoption of advanced IT tools within warehouses and distribution centers (DCs). Consequently, a comprehensive warehouse audit program and plan are required to evaluate this intricacy and uncover potential blind spots.

Ultimately, the primary purpose of the categories mentioned earlier and the questions included in this warehouse audit tool is to steer you toward adopting best practices in warehousing operations.

Over the past decade, warehouse operations have become more complex. This complexity is evident in the adoption of advanced IT tools within warehouses and distribution centers (DCs). Consequently, a comprehensive warehouse audit program and plan are required to evaluate this intricacy and uncover potential blind spots.

Ultimately, the primary purpose of the categories mentioned earlier and the questions included in this warehouse audit tool is to steer you toward adopting best practices in warehousing operations.

Additional Tools to Improve Logistics Performance

- Best Warehouse Safety Audit Tool to Improve Safety Performance and reduce accidents and injuries in the Warehouse environment.

- Materials Management Competencies Assessment to improve the performance of the team.

- Inventory Optimization Tool in Excel that will identify E&O, recalculate Safety Stock, identify changes in Made-to-Stock, and Made-to-Order, and redo the whole ABC analysis and more in minutes & hours rather than days.